Adding a Flatbed UV Printer can be a great way to grow your business, but buying a machine that doesn’t meet your current or future needs can be very frustrating, wasting both time AND money.

A little homework upfront when choosing your flatbed UV printer will help you make the right choice.

This article is intended to BE that homework and get you farther down the road to making your decision. By the end of the article you should know:

3. What the next step is to learn more or get started.

Important Questions Before you Buy a UV-LED Printer

Some fundamental questions to ask up front before you even start looking at machines would be:

- What do you want to print and how many do you want to print at once? Size Matters!

- Can you set yourself apart by printing DEEP items? (Flatbed UV Printer like the iU600s print the tops of assembled, not-flat products like boxes, awards, etc).

- Is space restricted? (Even small format flatbed UV-LED Printers take up space. Can you spare the room)

By answering these questions you can quickly begin to reduce down the list of printers to choose from.

Print Area and UV Printing

When determining what print size you will need it pays to consider not only the maximum single image you will need to print, but also look at logical multiples of that image.

Example: When the largest image is an 8.5 x 11” you will only be able to print one at a time on a typical small format led-uv printer.

Small format LED UV Printers normally have a 12” x 11” or 10” x 14” bed, so you can only print one image at a time.

You could print two on a printer with a 10” x 24”, 19” x 13” or 16.5” x 24” bed.

The Compress iUV600s is a mid format flatbed UV printer with 24” x 17.7” bed so you can print four images at one time. When moving up from small format to mid-format machines you will find that you can print 10 at a time on a printer with a 23.8” x 48” bed and 13 on a printer with a 45.3” x 29.5” bed.

If your business is about higher production and will involve larger runs of items then a larger print field can mean less user interface time with the printer and more time actually printing.

That means more money in your pocket just by printing the same size that the small format printers can. You’ll do even BETTER when you can offer printing one 16”x24” image on a sign or some other item because none of those others can offer that product.

Printing DEEP with Flatbed UV Printers

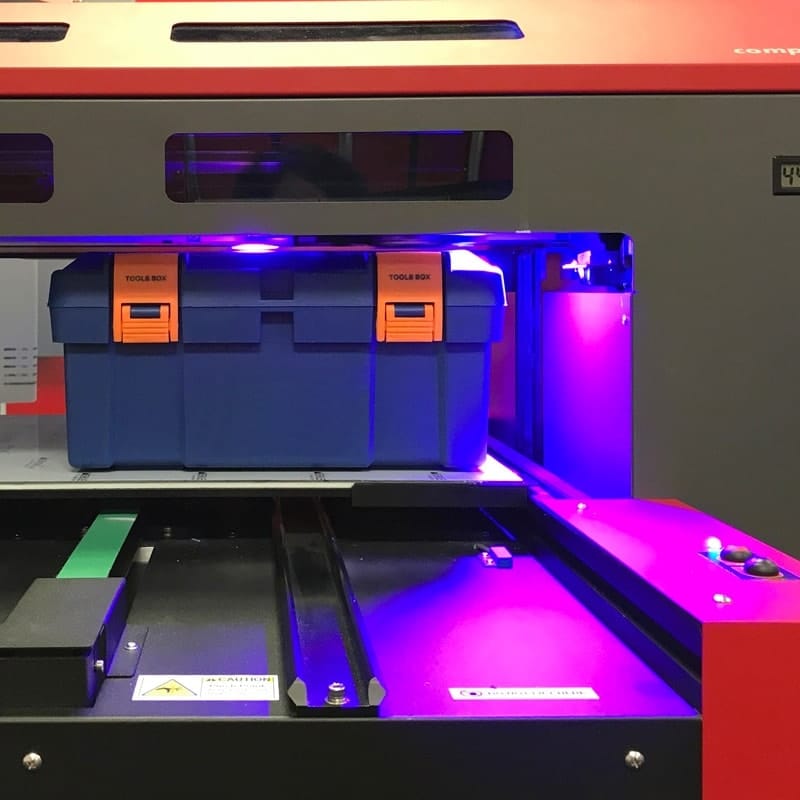

Another thing to consider is the height or depth of the items you will be printing. Take into account that many items will need some sort of jig or support mechanism to hold them in place while they are printed.

In the case of items like golf balls, this could add an additional .5-1.0” to the height needed. When you print on prefabricated items then you will find that the more depth the better. Print height can range from as little as 1.8” to nearly a foot, with the norm being around 5-6”. Having the ability to print “taller” items can open up markets that the typical flatbed UV printer cannot touch.

Here are a few applications for printing DEEP that will help you earn more customers and more money:

- Printing Basketballs

- Printing Baseballs

- Printing novelty bats

- Printing on boxes

- Add color to acrylic trophies – top or bottom

- Customizing gift items like ornaments and more

The more versatile your printer the greater the earnings potential.

Do you have the Space?

UV printers are not small and even small format UV-LED Printers can take up significant room. The general rule is the larger the prin area, the larger the printer. With that in mind, space may be a real concern in your location, so it is important to determine home much space you have available and the width of the doors and hallways leading to where the printer will need to reside.

It may be that a mid-format UV Printer is a perfect device to help propel your business to new heights, but you just don’t have the space for it yet!

The Important Parts of OWNING and OPERATING a Flatbed UV Printer

By answering the questions above you should have pared down your options to a few machines or maybe even less. So now you can start digging a bit deeper.

Here are the next wave of questions to ask related to how fast you can be up and running, what the overall capabilities are, and what it will cost you over time:

- Training and Installation – is it provided? What does that entail?

- Technical Support – do you feel confident that the company you’re buying from can not only help keep you running, but can be a problem solving partner over time.

- Software – the Compress UV Printers all come with a RIP software that performs some vital functions in the operating of your machine and the cost of the output. Is it included?

- Cost of inks

- Realistic productivity of the machine

- Machine cost with everything you will need to get started?

UV Printer AND Ink Cost

The questions of costs of inks and machine with everything needed should be pretty straightforward. Most machines on the market today sell for between $25,000 and $85,000.

Some UV Printers use bulk inks, some use cartridges or bags, so it will take a little homework to compare. To determine liter costs of uv inks in bags or cartridges simply divide cartridge price by the milliliter count and mulitply by 1000.

Ink prices vary widely from $250 per liter to over $700 per liter. If one ink is $250 a liter and another is $500 per liter then it is safe to assume that costs per print will be roughly twice us much on the machine with the $500 per liter ink as on the one with the $250 per liter ink.

Someone using 2 liters of ink per month (about average for most small to mid-format users) may spend an extra into $6000.00 per year in added ink costs depending on what flatbed uv printer you choose!

Training = Success

Is training included with the machine? If so, is it at your location, online or at the vendor’s location? If not, how much additional is training. What about future training – is it available? If so, is there a charge for additional training?

RIP Software – Vital Part of Every Package

When it comes to software most printers will include a RIP (Raster Image Processor) to drive the printer, though some offer it as an option (although it is a “required” option!). Questions to ask about the included software include – what file formats does it support (PSD, PDF, TIF, EPS, PNG, etc.), does it support or create texturing, variable data, serialization, and bar coding? Lastly about the software, does it support templates or do you have to set everything up in your design software properly spaced and aligned?

Productivity and Your Flatbed UV Printer

Now, the hardest question to get answered with a direct answer. What is the realistic productivity of the machine? The best way to determine this is to have a representative cross-section of images printed on the printer in realistic numbers (based on your expected order sizes). From these numbers, you should be able to get a good idea of how many items you can print in a typical work day and be able to determine the ROI of the machine based on them.