This problem-solving technology and why it matters to YOU

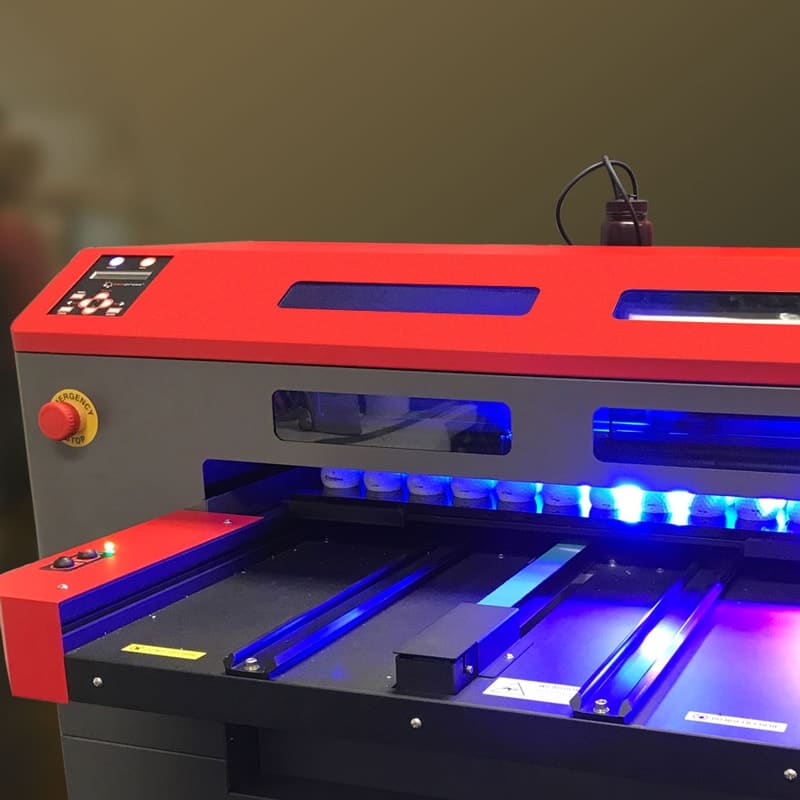

So, you’ve heard all the craze about UV-LED flatbed printers for printing directly on to a whole range of products that you didn’t think could be direct printed. You may have even seen them at a trade show or in someone’s shop.

But do you really know what they are and how they work?

Let’s look at the history of these printers to get a better understanding of where we are today.

UV LED Printer Printing Methods

Basically, there are two genealogies to track here. One would be flatbed printers and second would be UV, specifically LED-UV printing.

Flatbed printers have been around since the very early 2000’s. Many of the initial flatbed printers were based on existing wide format Epson inkjet printers. Those were converted or repurposed to either transit the head assembly over a flatbed or to move a flatbed under the head assembly.

So either the print head moves around a bed or small table and jets ink onto whatever is there (substrate)

Or the bed moves around UNDER the print head and accomplishes the same result.

Even today there are still a number of flatbed printers that use repurposed print engines as their core.

Today’s flatbed printers fall into the same two formats – let’s call them moving head and moving bed. They each have their own benefits and shortcomings.

Pros and Cons of UV Printing Methods

Moving head flatbed printers have a gantry system that runs on a track over the fixed position bed – similar to CNC, rotary engraving and routing systems.

For the most part these type printers are very large and have limited Z-axis travel (Z-axis refers to how far up and down the head can travel). Because of these features these machines are normally used for large signage applications with print areas in the 4’ x 8’ and upward range.

They also tend to extend further outside the print area than moving bed flatbed printers do. One of the key benefits of these printers is that they can oftentimes hold much more weight than the moving bed type printers as the media stays fixed and doesn’t need to transit though the machine.

Moving bed flatbed uv printers rely on a fixed position print track and a bed that moves the media under the print track.

The printers themselves have a smaller footprint relative to the print area than the moving head machines do, but the media moving in and out of the machine requires more clearance front and rear. Many moving bed printers have much more print depth (Z-axis) than the moving head units.

Typical depths of this type of printer range from 5.9” to 11.8”, like the Compress iUV600s and iUV1200s for example, and even more for custom built machines. This allows for much more versatility in the types of pre-assembled items that can be printed.

Because the media is being moved through the machine by a belt or screw type system the weight limits on these printers are generally lower than on the moving head units.

However, for most small to mid-format applications a moving bed type of printer is still the best choice.

And, in fact, most operations that are not doing large format signage will choose to use a moving bed type flatbed UV printer.

Curing Method Options

How do LED UV Printers dry the ink without a separate curing process, like a dryer?

The earliest UV printing systems used mercury vapor lamps to cure the inks which operate in a wider range of the UV spectrum.

These types of lights are good for curing large areas but are less efficient because they are omni-directional. That means that the light emits for them in all directions thus requiring a reflective system (mirrors) behind and around the sides of the lamp top focus the energy towards the print source.

They produce more heat on the surface of the material being printed which can cause thinner and heat sensitive materials to pucker, wrinkle or warp. In comparison to what you’ll read about next, the lights are short lived as well.

Most of these type lamps have an “on time” life of about 2000 hours. Similar to the lights in your old high school gymnasium, they require a warmup time to be effective.

The UV-LED Printer Lamps Advantage

LED technology was developed for the electronic circuitry marketplace but have become more and more important in the lighting market – ranging from household and business interior lighting to signage and traffic applications.

UV-LED lamps are unidirectional – meaning the light is focused in one direction – and 30-50% more efficient than mercury vapor lamps. They create less surface temperature than the mercury vapor lamps as well – allowing for the printing of thinner and more heat-sensitive materials.

These lamps are also much smaller and lend themselves to the small to mid-format UV printers. Beings smaller printers, they require smaller curing lamps.

While LED UV lamps tend to be more expensive than mercury vapor lamps, they last on average 10 times longer – thus offsetting any cost difference between the two lamps types very quickly.

LED lamps perform well across the full spectrum of their power, while mercury vapor lamps do not perform as well at anything below full power. That means that they go from 100% performance to 0 on a curve.

So you’ll need to watch the end result, your printed sign or promo product, to determine when it’s time to replace them. And obviously, at that point, you’re delivering less than your best work.

Lastly, UV-LED lamps are instant on and instant off – no need to extend warm-up and cool downtimes.

UV Printer Inks

Whew! Now we know about flatbed printers and the types of lamps used in UV printers. Only one more thing to wrap our heads around. Let’s discuss the inks.

The most common type of inks we think of when we discuss inkjet printers are water-based inks and solvent based inks. Both of these inks are cured by heat and/or time.

When these inks are exposed to heat from the air or an external source they will dry giving off some form of gas (either water or solvent based) thus reducing the total volume of post-cured ink versus pre-cured ink.

UV printer inks are different.

UV inks are a mix of monomers (small molecules that are the building blocks of polymers), oligomers (small polymers) photoinitiators and pigments (colorants). Basically, when the photoinitiators are exposed to UV radiation they release extremely reactive atoms and molecules that cause polymerization.

Stay with me, that’s the bonding of the monomers and oligomers which are also holding the pigments and moving from liquid to solid (all of this in a split second by the way).

So when the UV light hits the UV ink it goes from liquid to solid immediately.

Your inks are now cured. No off-gassing/evaporation like means that there is less ink sinking into the material – so less ink is needed. Have you ever heat pressed a DTG shirt? You can see the steam coming off the water based inks. Not so with UV.

Because there’s no evaporation the ink does not lose volume. Because of the “existence” of the ink on the surface of the material once it is cured we are able to “build up” the ink to give texture to prints.

Print layer one and it’s immediately dry so we can print layers 2, 3, 15 right in the same spot, right away. That’s texture.

It can be used to highlight areas, create optical effects as well as produce tactile prints.

Why does this all matter to you?

Ok – now you are an expert on UV-LED Printers and understand how the inks work. So, why should you be interested in a UV-LED printer for your business?

- UV printers allow you to print directly on to substrates – up to 11.8” or more in height

- UV inks adhere to a lot of materials

- Unlike processes like sublimation, UV printers come with white ink which allows you to print on more than just while or light substrates

- With UV printers you can directly print “second surface” meaning that you can back print clear materials like acrylic or glass for beautiful effects while at the same time protecting the print

- Textured printing opens up lots of doors and allows for greater creativity from your artists