Everyone offers custom golf balls.

One of the reasons many promotional products vendors, and even sporting goods manufacturers, get into UV printing is specifically FOR golf balls.

After all – golf is everywhere and people will definitely spend on tournament logos.

But while golf balls are very popular, there’s also quite a bit of competition in the marketplace. So niching down into something a little more specific could be a BIG win for your customization business.

Offering custom ping pong balls could just put your business in a more profitable spot, using the same tools you use to do custom golf balls.

Printing Ping Pong Balls vs Golf Balls

Golf balls must be at least 1.68” in diameter, ping pong balls are 1.57” in diameter.

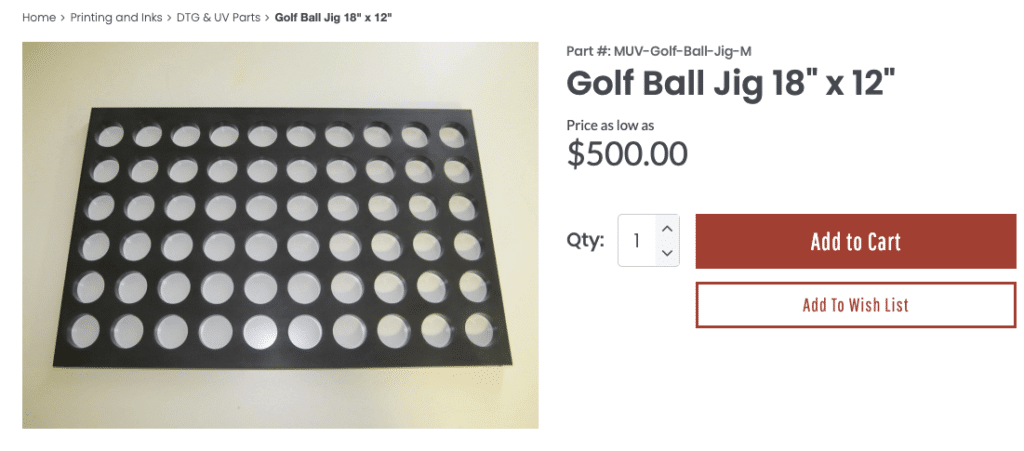

Because of this minimal difference in diameter, ping pong balls will fit nicely into the golf ball jig sold on Colman and Company.

And since both sporting goods manufacturers (of basketballs, volleyballs, and golf balls) have adopted our Compress UV Printers we decided to test ping pong balls as well.

Here’s what we found.

- They print beautifully at fine print mode, no need for extra fine mode

- When cleaned with isopropyl alcohol the adhesion is excellent

- You can print 60 balls on the jig – making it an efficient process – full bed print time would be approximately 6 minutes.

- They are inexpensive to print – we printed 20 ping pong balls and the total ink cost for all 20 balls was one half a penny! A bed of 60 balls would cost slightly more and a penny and half to print.

- It is totally conceivable that you could print 540+ ping pong balls per hour.

Ping pong balls don’t need to be used just for ping pong – games like beer pong use these balls, bingo and lottery machines use these type balls, they can be decorative like “eyes” for Halloween – the list goes on.