DTF and UV DTF printers have notable distinctions that impact their suitability for different applications. DTF printers operate with DTF film, DTF powder, and DTF ink, while UV DTF printers use UV ink and AB film.

DTF printers need powder and oven drying, whereas UV DTF printers rely on UV light and laminating. DTF excels with soft surfaces like t-shirts and hoodies, while UV DTF is better suited to hard-surface items.

DTF and UV DTF Differences in the Printing Process:

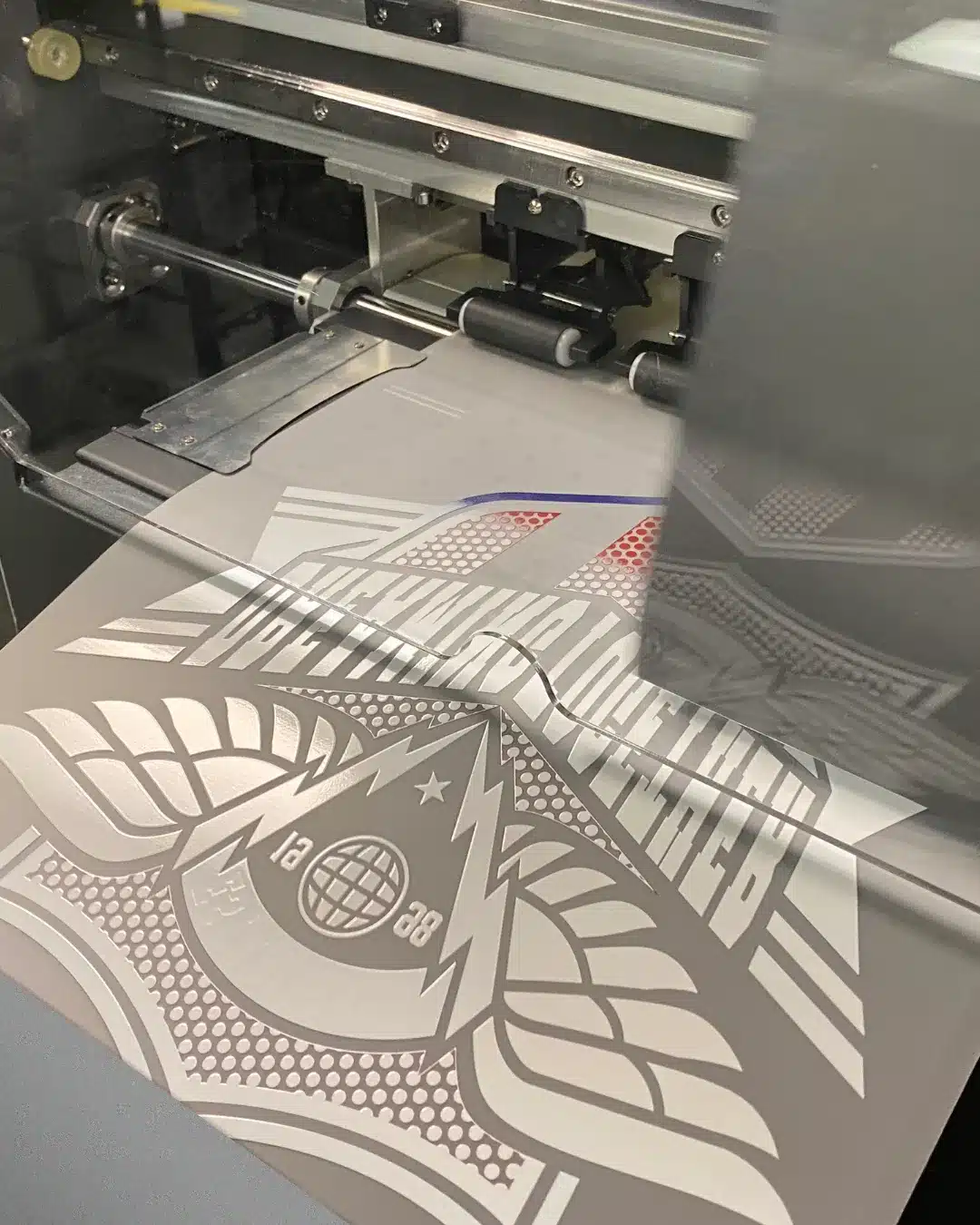

- DTF: In DTF printing, a design is printed onto a special film using a DTF printer. After the adhesive powder has been applied and cured, the printed film is then transferred onto the garment using a heat press, where the design adheres to the fabric.

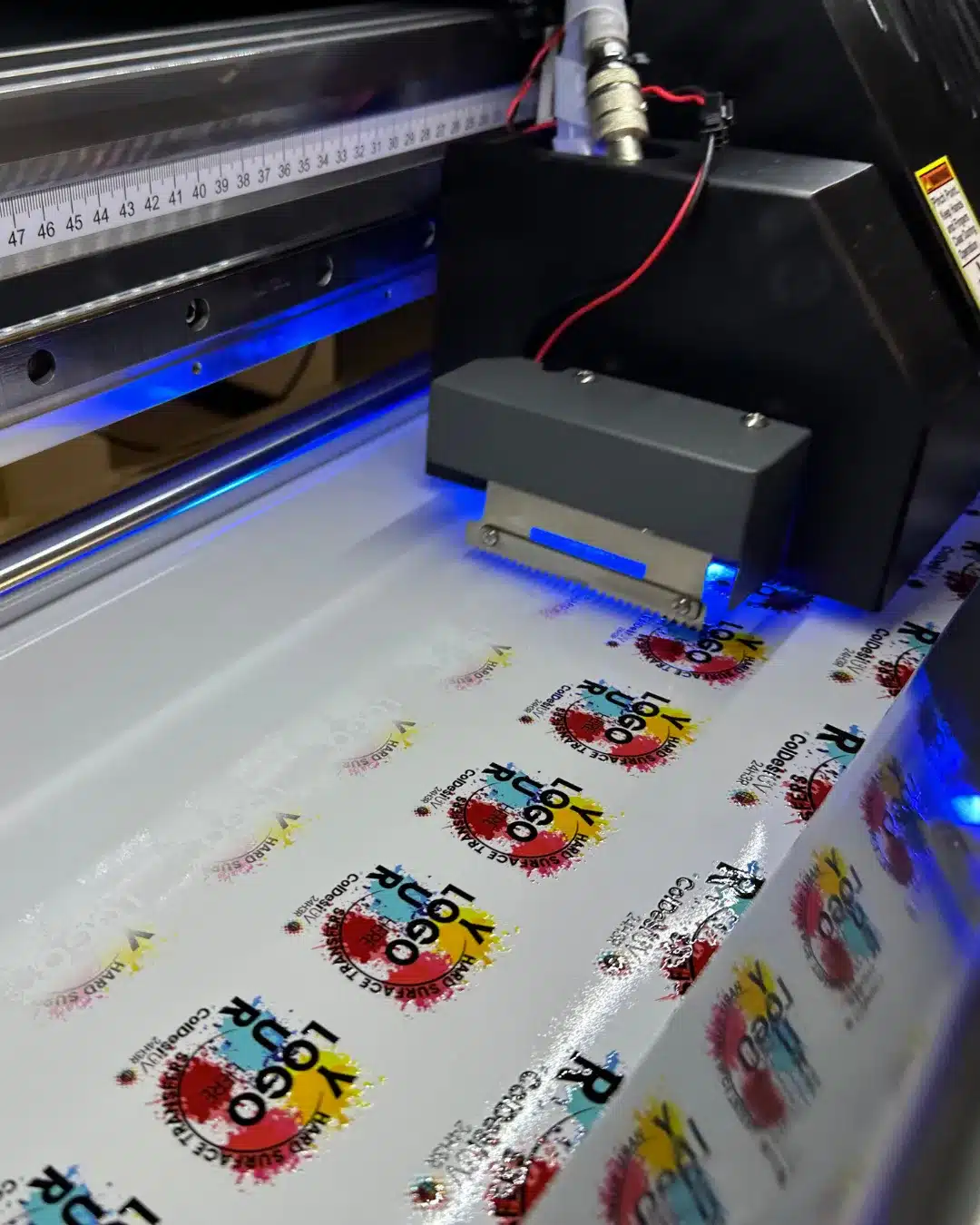

- UV DTF: UV DTF printing also involves printing a design onto a film using a specialized printer. The ink used in the printing process is cured instantly using UV light, which helps in faster drying and adherence of the design to the substrate.

Ink Used: DTF and UV DTF

- DTF: DTF printing typically uses a special type of ink that is compatible with both the film and the fabric.

- UV DTF: UV DTF printing utilizes UV-curable inks, which are exposed to UV light to solidify instantly. These inks often offer better durability and color vibrancy compared to traditional DTF inks.

DTF and UV DTF Drying Time:

- DTF: DTF printing usually requires a certain amount of time for the ink to dry before the design can be transferred onto the fabric.

- UV DTF: UV DTF printing significantly reduces drying time, as the UV-curable inks dry almost instantly upon exposure to UV light.

Durability of DTF and UV DTF:

- DTF: The durability of DTF prints depends on the quality of the ink and film used. Generally, DTF prints are durable and can withstand regular washing and wear.

- UV DTF: UV DTF prints tend to be more durable due to the instantaneous curing of the UV-curable inks, resulting in better adhesion to the substrate.

Color Vibrancy of DTF and UV DTF:

- DTF: DTF prints can have vibrant colors, but the color intensity may vary depending on the quality of the ink and film.

- UV DTF: UV DTF prints often have excellent color vibrancy and sharpness, thanks to the quick curing process of the UV inks.

Learn more about the DTF Printing Process:

Different Applications of DTF and UV DTF

Applications of DTF:

Garments: DTF excels in the garment industry, with the ability to produce high-accuracy patterns with vibrant colors.

They are particularly well-suited for printing on fabrics, making them ideal for a wide range of apparel items, including:

- T-Shirts

- Hoodies

- Pants

- Blouses

- Hats

- and More

Textile Printing: DTF is also used for textile printing applications beyond garments, such as printing on fabric panels for banners, flags, and other promotional materials.

Applications of UV DTF:

Hard Substrates: UV DTF is designed to print on hard substrates. They are used in various industries for printing on surfaces such as:

- Glassware

- Mugs

- Tiles

- Phone Cases

- Luggage

- and More

Home Decor: UV DTF printers are utilized in the home decor industry for customizing items such as ceramic tiles, glass decorations, and wooden plaques.

Advertising and Retail: UV DTF printing finds applications in the advertising and retail sectors for creating personalized promotional items, signage, point-of-sale displays, and branded merchandise.

DTF vs. UV DTF: Benefits

Benefits of DTF Printing

- Versatility: DTF printing is suitable for almost all types of fabrics, regardless of color, making it highly versatile for various garment types and designs.

- No Pretreatment Required: Unlike some other printing methods, DTF printing does not require pretreatment of the fabric, streamlining the printing process and saving time.

- High Printing Quality: DTF delivers excellent results with high precision, vibrant colors, and clear patterns, ensuring exceptional quality in the final product.

- Durability: Printed designs from DTF printing exhibit good washing and rubbing characteristics with minimal cracking, even when stretched, ensuring the longevity and durability of the printed garment.

- Flexibility in Production: DTF printing allows for flexible batch sizes, enabling both single-piece production and larger lot-size production. It offers the freedom to revise images or patterns as needed, facilitating fast turnaround times and short production cycles.

- Environmental Friendliness: DTF printing is environmentally friendly, with low energy consumption, minimal pollution, and low noise throughout the printing process, contributing to reduced industrial pollution.

- Cost-Effective: DTF printing offers cost savings in various aspects. The digital printing machines require minimal space, reducing site and building costs. The operation is automated and efficient, requiring minimal labor, thus lowering labor costs.

- Simple Maintenance: Daily maintenance of DTF printers is straightforward, and the maintenance costs are low, ensuring smooth operation and minimal downtime.

The benefits of DTF printing make it an attractive option for garment printing, offering high-quality results, flexibility, cost-effectiveness, and environmental sustainability.

Learn more about ColDesi’s line of Commercial DTF Printers.

Benefits of UV DTF Printing

- Customize Sloped Surfaces: UV DTF printers can customize surfaces with slopes or irregularities, enhancing versatility and opening new possibilities for printing on a wider range of objects.

- Supports Varnish Printing: UV DTF printers have the capability to perform varnish printing, allowing for the application of glossy or matte finishes to printed designs. This feature adds depth and dimension to the prints, enhancing their visual appeal and creating unique effects.

- Ease of Transfer: UV DTF printing simplifies the transfer process, making it quick and straightforward. This efficiency ensures high productivity, particularly beneficial for fulfilling small orders or projects with tight deadlines.

- Simple Printing Steps: UV DTF printing involves straightforward printing steps, minimizing complexity and streamlining the printing process. This simplicity saves time and reduces the likelihood of errors, contributing to efficiency and productivity.

Learn more about the ColDesi UV 24H3R Direct to Film Printer.

DTF or UV DTF: Which to Choose? Why?

Choosing between DTF and UV DTF depends on several factors. If you’re focusing on garment printing, DTF would be the ideal choice. DTF printers excel in printing on textiles and leather, offering a wide range of shades and hues.

They are also more cost-effective for bulk orders, making them suitable for businesses with high-volume printing needs in the garment industry.

If you’re looking to print on hard substrates, then UV DTF would be more suitable. UV DTF printers are compatible with a broader range of materials, offering advantages such as vibrant colors and excellent durability.

The ink dries immediately upon exposure to UV light, speeding up production and ensuring clarity and color intensity in the printed image.

UV DTF printers integrate the advantages of both UV and traditional DTF printing technologies. These printers can print transfers for a wide range of surfaces with high accuracy and produce high-quality patterns with vibrant colors.

The choice between UV DTF and traditional DTF depends on your specific requirements, as well as budget constraints and preferences.

If you prioritize durability and versatility on various substrates, UV DTF printing might be the way to go. If you are focused on fabric printing and value cost-effectiveness, a traditional DTF printer could be the better option.

Are you looking for the next machine to expand the company? ColDesi offers a solution for any customization need. Combined with our premium training and support, the path to starting or growing a business is an easy decision, empowering entrepreneurs with the tools and knowledge necessary for success.

To learn more about ColDesi’s complete line of customization solutions, visit our website coldesi.com, Live Chat with a Pro below, or call 877-793-3278.