Printing in-house can provide a better return on investment, as opposed to subcontracting the work out to a pad printing supplier.

Many of your customers who order custom apparel from you also purchase promotional materials. Or if they don’t, they either don’t know where to get it done or haven’t thought about where to buy pad printing supplies..

Your customers trust you with their custom apparel, why not make yourself their one-stop shop for all their custom needs?

Oftentimes custom apparel businesses will subcontract out work for things they can’t do in-house. Whether it’s other types of custom apparel – rhinestones, vinyl, etc. – or promotional items such as pens, printed bags, and golf balls.

Subcontracting still allows you to make a profit off your customer’s order. However, the profit isn’t as high as if you took that printing in-house. Not to mention it allows you to create inexpensive promotional items for your business. Without the need to constantly get supplies from your pad printing supplier.

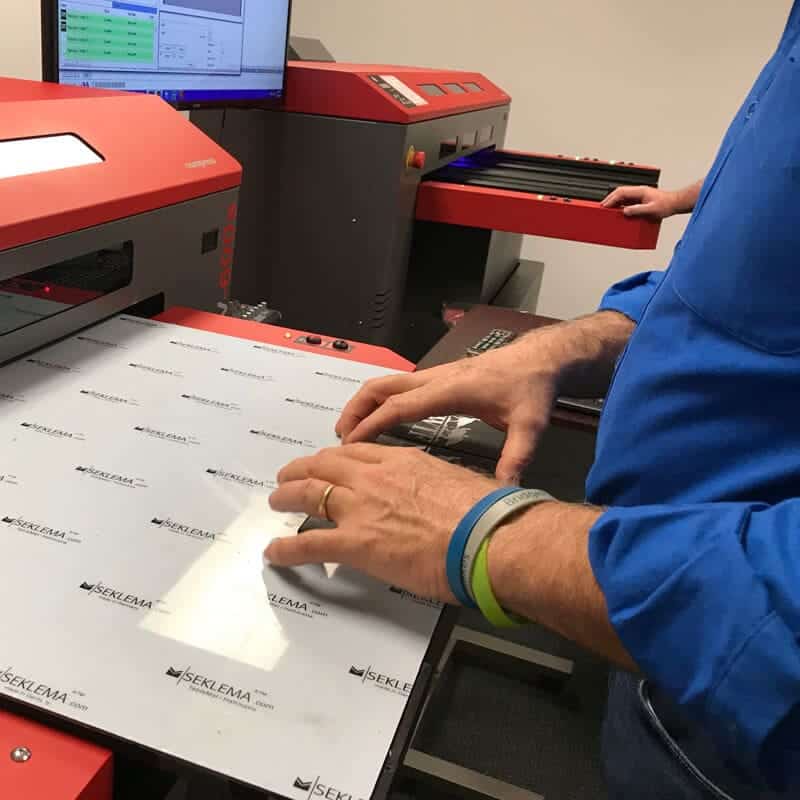

LED UV Printing

LED UV Printing is a better alternative to Pad Printing. It allows you to print on any number of different objects, plus allows you to print onto multiple items at a time, in full-color. Check out our page of UV applications here.

The UV printer allows you to print on signs, magnets, boxes and packaging materials, yeti mugs and cups, golf balls, basketballs, the list goes on.

The Compress iUV600s has a 24” x 17.7” bed, while the 1200s is 44.75” x 29.5”. Both allow you to print on large items or multiples of the same item. The large surface area means you’re not spending as much time swapping out items to be printed on. Your pad printing supplier won’t be too happy.

This alone can save you money as you’re freed up to work on other aspects of your business while the machine is running. And with all the supplies in-house, you’ll never have to ask “where to buy pad printing supplies?”

ROI

UV Printers can range from $25,000 – 85,000 depending on the size of the bed. Ink can also range from $250 – 700 per liter. However, the cost of ink per item tends to be minimal.

To give you a better of the ROI of a UV printer, The Compress iUV600s is $36,995.

Custom Phone Cases

- $1.00 /case

- $0.065 in ink per case

- Total cost = $1.07/case

If you went to the store you would easily pay $25 for a phone case. Using that number your profit per case is $23.93.

15 cell phone cases can be printed at once. At 7 minutes per run, you can easily print 8 runs or 120 cases in an hour.

Profit per hour = $2,871.60.

Just like in the example above, even taking an additional hour or two to create custom designs, still makes this product incredibly profitable.

Custom Phone Cases

- ¼ inch acrylic, 27” x 8” = $10/sheet

- $0.60 ink per sign (White under base + color coating)

- Total cost = $10.60

You can easily sell these signs at $50/piece. Making your profit per sign $36.40.

With printing two signs at a time, the printer takes about 6-7 minutes each run. Including the time it takes to set the next set of acrylic and start the machine, conservatively you can print up to 12 signs in an hour.

This means your profit per hour is $436.80 ($36.40 x 12). You’re also likely going to need some design time before printing, for this example, we’ll say it takes an additional hour per 2 signs.

Your new profit per hour is $218.40.

Using those numbers, let’s say you fill 3 jobs per day, 15 jobs per week. That’s a total weekly profit of $3,276.

If you have steady business, your UV Printer has paid for itself in just over 11 weeks (36,995 ÷ 3,276).

Advantages of LED UV Printing

In addition to the incredible ROI of a UV printer, there are a number of reasons why you should consider adding this to your business over subcontracting to a pad printer.

- Full-color printing – Most pad printers only do one to two colors (and 6 max). The printer might not be able to print the design you want, plus more colors increase the cost.

- Quality images – Just like if you were to go to have photos printed out, the UV printers create incredibly high-quality images. You and your customers don’t have to simplify the images to make it look good.

- Multiple products – From wood to acrylic, to basketballs, to cardboard, and clay tiles the UV printer can create images onto almost any surface.

- Textured surfaces – Even if the surface of the item is textured – such as golf or basketballs – you still get high-quality images. Because with pad printing you’re pressing the ink onto the product, some spots may not get ink onto them if the indentations are too deep.

One of the cool things you can do with the UV printer is print both on the front of the acrylic and the back. This can give the image a 3D effect. For example, the back can have a dark cityscape, while the front could have different aspects of the cityscape and the company logo.

Two other great aspects of UV printing are white under base and varnish. We also make it easy to buy pad printing supplies.

The white under base is really great for ensuring the image stands out from the product. We often do this with the acrylic signs and clay tiles, any product that isn’t already white.

The varnish allows you to create matte and glossy images. This really gives you an edge on the competition as you can further customize the product.

To see the LED UV Printer in action check out our UV Printers Playlist on YouTube.