Best Methods for Printing on Acrylic Glass

Printing acrylic glass signs can be a challenge without the right equipment. There are lots of ways to print on acrylics, but if you plan to do large glass signs, some methods are better than others.

Some people will print acrylic glass sublimation equipment; others will cut vinyl and apply it to the signs. Still, others will laser etch the signs.

But if printing beautiful and durable acrylic glass signs are more than just a hobby, nothing has the versatility, speed, and profitability of using a small format UV printer.

And one of the hottest new small format UV printers to hit the market is the Compress iUV600s UV printer, and its larger cousin, the Compress iUV1200s.

Advantages of Printing Acrylic Glass Signs with a Small Format UV printer:

First, a UV Printer is not just an acrylic glass sign printer. That’s just one of the more profitable things you can do with it.

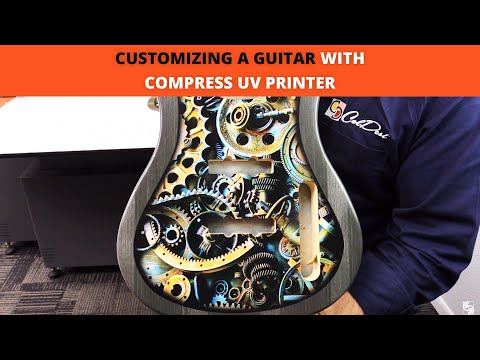

However, before you read any further, check out this short demonstration video to see how well the Compress UV machine does printing acrylic glass signs.

Knowing how it works, we’ll break down the advantages of a UV printer vs some of these other technologies.

Advantage #1 | Versatility=Profitability

Surprisingly, the first advantage to using a small format UV printer for printing acrylic glass signs is that you can do so many other things with it. You’re not locked into only one application with these UV printers.

You can make tons of unique signs all in high-quality full color with the same printer that you’re going to use to make acrylic signs.

Here are a few examples, watch videos on the right of each of these applications:

- Make Custom Wood Signs – you can print directly on even unfinished, uneven wood surfaces

- Coroplast signs – very popular for making real estate signs, political signs and temporary directional signs.

- Printing on magnetic material – you can use your Compress small format UV printer to put full-color images right onto magnetic materials. Perfect for making vehicle signage.

- Printing on METAL signs – one of the big differences between using a UV printer as a sign printing tool is that you don’t need special blanks. Just buy metal sign blanks and you can make full-color parking signs and more

These are just the obvious applications if you’re in the sign business. But UV printing with the Compress printers brings a whole world of promotional products and industrial marking applications to your shop as well.

The small format UV printer is highly versatile which makes you more profit on MORE things.

Advantage #2 | Low Materials and Supplies Cost = Profitability

In the video, you saw that two signs were being printed at once. Let’s check out the cost of producing this job.

The blanks were cut from a 4×8 acrylic sheet.

The pieces in the video were about 27.5” x 7.5” which ended up costing right around $10 each.

The ink used for BOTH signs was $1.26. While ink use for each print wasn’t the same it’s safe to estimate ink cost for 1 sign at $.63

Each sign cost $10.63 for us to produce.

We shopped for the same custom acrylic sign online and were able to use an online designer to get a retail price. The same sign with the same design printed on the same size piece of acrylic was $61.79

Retail Price $61.79

Even if you were to offer your customers the same one-off custom acrylic sign for $50.00, which you could print while they waited, you would make $39.37 in gross profit.

That’s a Gross Margin of over 78%.

There’s just no other method for printing acrylic signs that offer you that kind of profitability combined with the versatility we’ve already proven.

Advantage #3 | Workflow = Profitability

If you’re printing signs now, imagine a day when you could have a customer come in with a good graphics file to have a custom acrylic sign printed.

Now imagine after just a few minutes of file and printer prep you could load up your blanks and hit print – while your customer waits.

Just in case you didn’t notice in the video above. We printed 2 different custom acrylic signs at once.

And they were ready for delivery – completely done – when we took them off the Compress UV printer.

No drying – No cutting – No applying – No weeding – No finishing – No waiting

Can you sell that “while you wait” service?

Even if that’s not your business model, think about the labor you’ll save. Think about the mistakes in processing you can avoid. Think about the ability to handle fast turnaround times. About the space you’ll save not having large weeding tables, space to layout and dry, separate finish areas.

Think about the money you can make and the hassles you can avoid printing acrylic signs with the Compress UV printer.

Also Works for Printing BIG Acrylic Glass Signs

You are not limited to the 24” x 17.7” print area of the Compress iUV600s small format UV printer.

Watch the video to see the iUV1200s acrylic sign printer with a 44.75” x 29.5” print sign too.