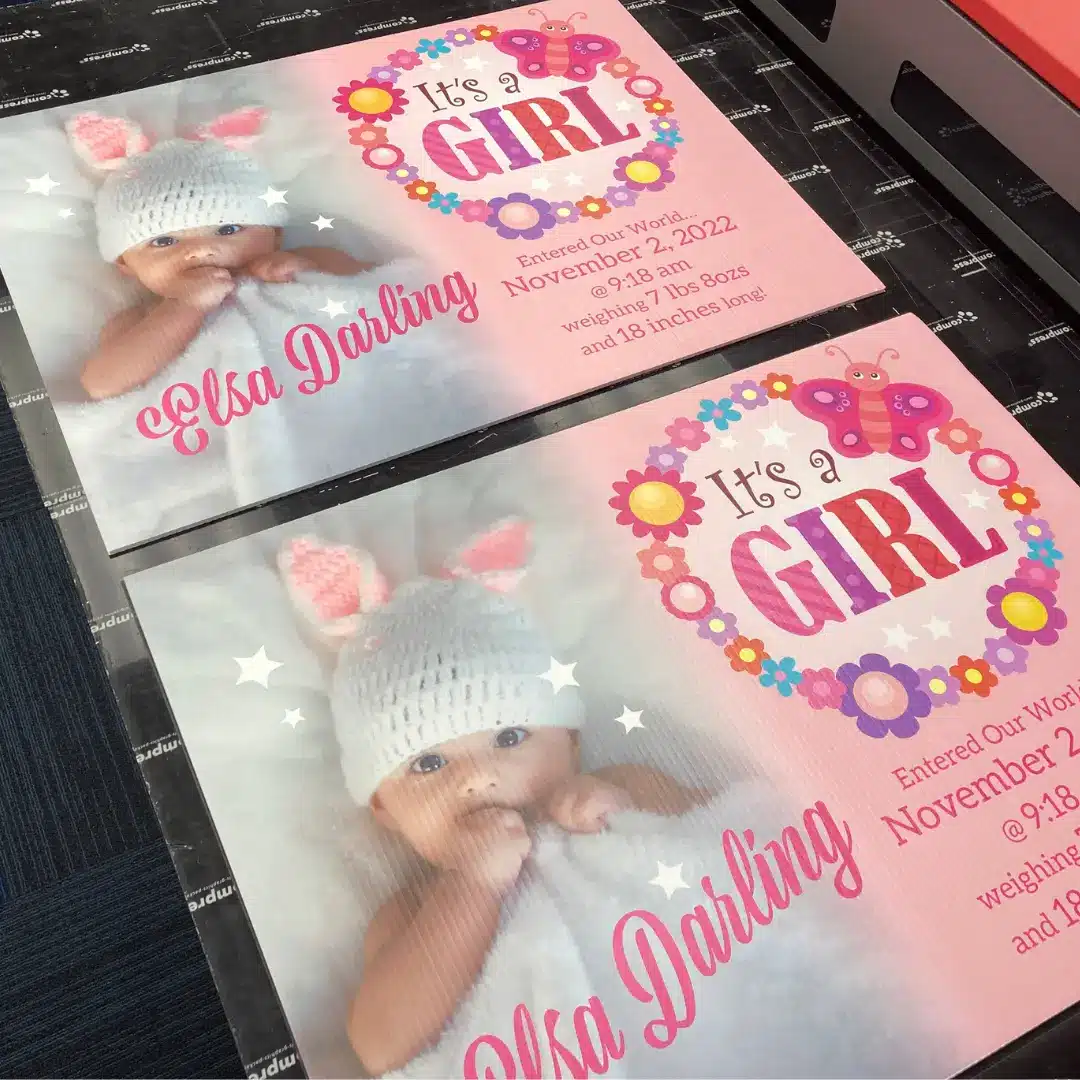

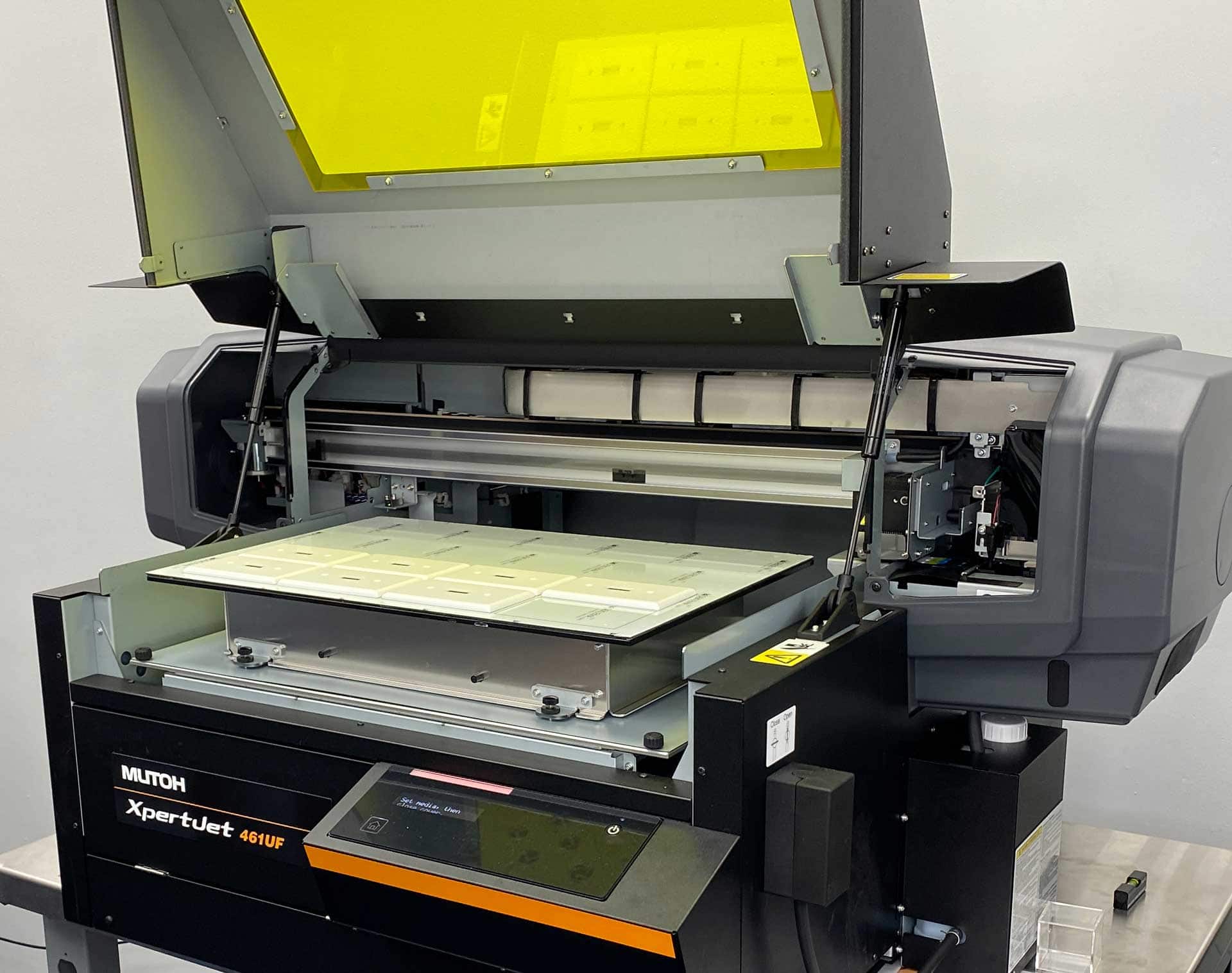

UV flatbed printing offers fantastic new opportunities for an established large-format printing business, including printing directly on a wide variety of rigid and flexible substrates.

Besides the new products you can create, it has the capacity to produce them in larger quantities. With many options available, choosing a UV flatbed printer can be daunting. It is an investment, so it needs to be right for the present as well as the future.

Determining Your Need for a UV Flatbed Printer

Determining your need for a UV flatbed printer is necessary. Are you replacing outdated equipment? Expanding your production line?

Moving away from outsourcing? If you’re replacing an older model, consider if you want to stick with the same brand or switch to a more reliable one. If it’s an addition, think about how it will integrate with your current setup and software.

Finding a knowledgeable distributor who can guide you through the options is crucial. They can help ensure that your choice meets both your current and future business needs.

Understanding the Cost of UV Flatbed Printers

Understanding the cost of UV flatbed printers is important. Prices vary by brand and size. It’s critical to compare different brands and models to find one that fits your budget and meets your needs.

A higher price does not always equate to better quality. Consider what each brand offers: features, reliability, and support.

Leasing vs. Buying: Making the Right Decision for Your Business

Deciding to lease or buy depends on your financial situation and long-term goals. Purchasing outright is usually less expensive overall, offering faster acquisition and avoiding the high interest rates associated with leasing. Leasing can provide flexibility and quicker access to the equipment.

Consider the pros and cons of each option, including the impact on your cash flow and the potential benefits of owning versus leasing.

Aligning Production Goals and Substrate Requirements with Printer Capabilities

Production goals and substrates will influence your choice of a UV flatbed printer. Varied materials require different printer capabilities. Assess the size of the print bed needed for your projects.

A versatile printer offers flexibility and can manage various materials. Consider if you need white ink capabilities, as this will expand the range of substrates you can print on and enhance print quality.

Evaluate Substrate Versatility

- Material Compatibility: Think about media durability, weight, or aesthetics. Ensure the machine can manage what you are producing.

- Cost Optimization: Depending on the application, some substrates may be more cost-effective than others. Versatile printers allow you to choose the most economical substrate, optimizing production costs.

- Sampling: A printer capable of handling various substrates allows you to evaluate and showcase your designs on the intended production materials.

- Future Adaptability: As new materials and substrates emerge or gain popularity in the market, a versatile printer can adapt to these changes, keeping you competitive.

Consider Your Greatest Print Size Requirements

Understanding what products you plan to sell will determine the size of the machine you need.

Printing large signage or other oversized graphics will require a printer with a print area that can accommodate those dimensions.

Assessing Your Production Volume Needs

UV flatbed printers are available in many sizes and print speeds, catering to different business output requirements. The advantage of digital printing is its on-demand capability, meaning you only produce what you sell.

This minimizes waste and reduces the need for stockpiling. It is still important to choose a machine that meets demand efficiently.

- Study trends and identify your customers’ motivation to pay for your products. Analyze your competition’s pricing, product range, and market share. Identify gaps in the market that you can capitalize on.

- Develop realistic sales forecasts. Estimate the production costs, including materials, labor, overhead, and other expenses.

- Assess the potential for scaling up production volumes as demand grows, considering more equipment, workspace, and personnel requirements.

Evaluating Print Resolution, Ink Configurations, and Color Management

Ensuring Integration with Existing Equipment and Software

Integration with existing equipment and software is crucial for maintaining efficient workflows. Ensure compatibility with your current setup, especially if you have many printer brands and models. Many UV printers need specific software for processing and managing workflows. Most printers will include a RIP (Raster Image Processor) to drive the printer.

When evaluating the included software, consider the following questions:

- What file formats does it support (PSD, PDF, TIF, EPS, PNG, etc.)?

- Does it support or create texturing, variable data, serialization, and bar coding?

- Does it support templates? Do you have to use design software?

Considering Upfront and Ongoing Operating Costs

The upfront cost of a UV flatbed printer is a significant investment. It’s essential to consider the ongoing operating costs as well. Ink consumption, printhead longevity, and maintenance requirements can vary between models and manufacturers.

Research and compare these costs carefully, as they can have a significant impact on your profitability over the lifetime of the printer.

Managing Maintenance and Operational Costs

Maintenance and operational costs are crucial factors to consider. Ensure you have the resources to operate the printer effectively, including trained staff to manage and maintain the equipment.

Key questions to consider about training and maintenance:

- Is training included with the machine? If so, is it conducted at your location, online, or at the vendor’s location?

- If training is not included, how much does it cost additionally?

- Is future training available, and if so, is there a charge for it?