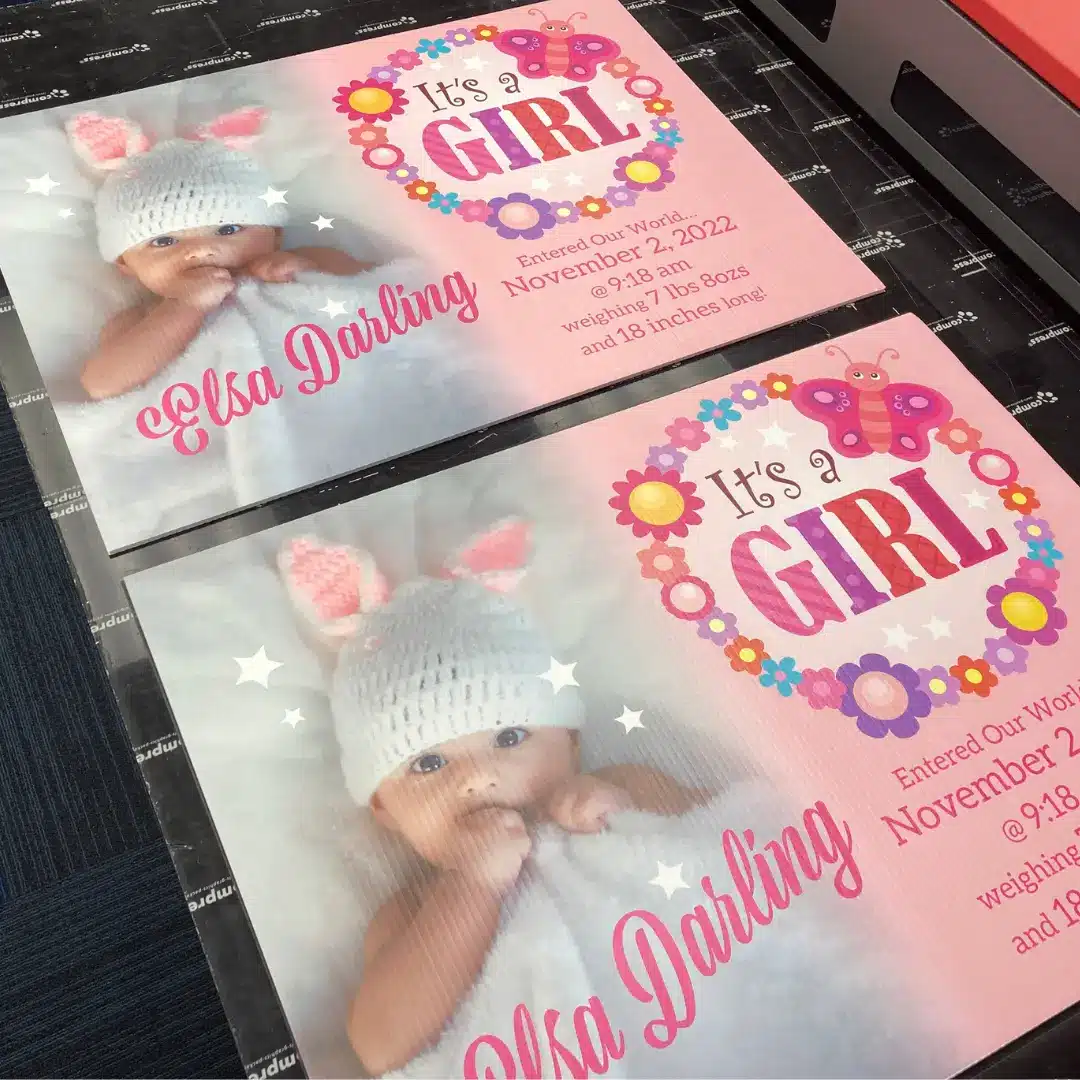

UV Printing is a digital printing process for both finished and unfinished hard surface goods.

For this printing process, the UV Printer applies inks directly to the desired surface. These inks are instantly cured with UV light and ready to use right after printing.

What makes UV printing unique?

1. UV printing provides a larger printing size than many other digital customization methods. Comparing the printing field of UV printers to the max print size of sublimation or white toner transfers showcases a night and day difference.

- Mutoh XpertJet 661UF Printer: 19.02” x 23.3” print field

- Compress iUV 1200S Printer: 44.8” x 29.5” print field

- Sawgrass SG1000 Printer: 13” x 19” Printed Transfer

- DigitalHeat FX 9541 White Toner Printer: 13” x 19” Printed Transfer

2. UV Printing provides unique hand feels that aren’t available to other printing methods. This includes textured prints. This will allow for a wide variety of images and textures, even braille signage. Understanding how to texture prints will open creative and business opportunities, which is perfect for any UV printer.

3. A UV printer is all you need to start or grow your business. Thanks to the special inks used with UV printing, that instantly cure under UV lights, there is no need to worry about any extra steps or any extra equipment besides your UV printer. Other printing methods even after printing still require time under a high-pressure, high-temperature heat press.

4. Compared to analog methods like screen printing or vinyl cutting, UV printing allows for printing many colors simultaneously. This means a 4, 6, 8 or even 100+ color print all take the same amount of time and effort, including printing white ink.

5.Variable data can be printed with a UV printer. This means that each individual piece you are printing can have a different image without any additional set up. (Name drops, numbering, bar codes, etc)

Steps for printing with a UV Printer:

- Design: Find a design either by creating one using design software, finding an image online, or purchasing a design file.

- Prep your printer: Load the design file into the printer software (included with the printer) and load your blank into the printer.

- Print: The printer takes over from here. The printer will apply the inks directly to the surface of the blank including curing with UV light.

- Sell: The result from the printer is ready to sell.

UV DTF:

While UV printing can print on nearly any hard surface, there are a few situations where you may be limited by that model of printer.

What items might be hard to print on?

- Conical items

- Multi-curved items (e.g. bike helmet, wavy surface)

- Very large items

- Completely manufactured goods (e.g. interior of a car)

That’s where UV DTF printing comes in. By printing a UV transfer onto film, the same unique texture and vibrancy can truly be applied on any surface, not just items that can fit into the printer.

Products that UV Printing works on:

Materials you can print on:

- Plastic

- Glass

- Wood

- Acrylic

- Carbon fiber

- Ceramic

- Fiberglass

- & Much more

What businesses / industries can benefit from UV printing?

- Sign shops

- Awards and Engravers

- Equipment manufacturers

- Wedding gifts & accessories

- Sports memorabilia

- Universities / Schools

- Military contractors

- Home improvement / decor

- Tourism / Resorts

- Sporting goods and equipment

- Automotive

- Industrial manufacturing

- & Much More

Want to know more?

For more information about the fast, versatile UV Printers contact us or call (855) 201-9185 toll-free.